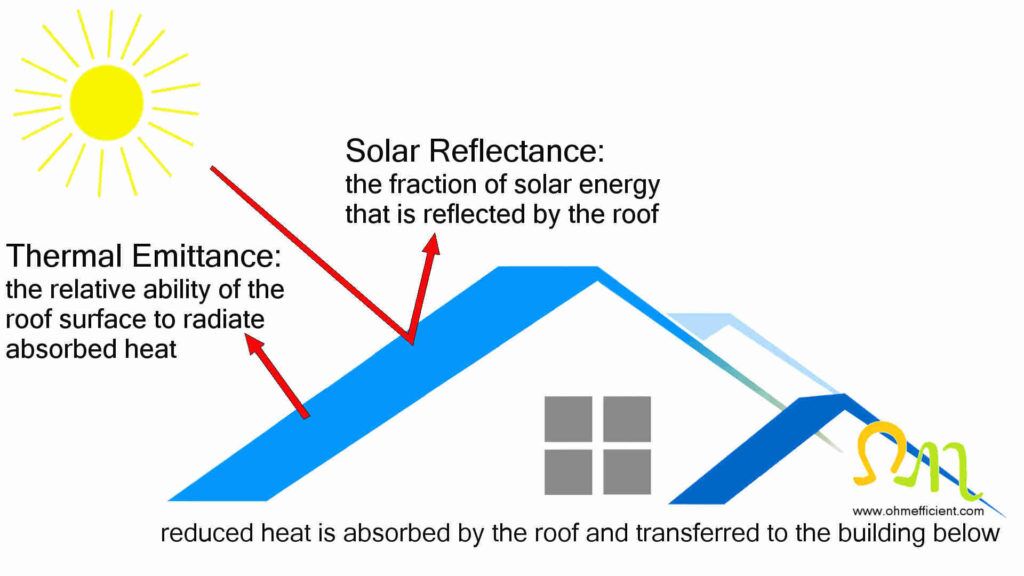

This article explains what a cool roof is and how they work to reduce energy consumption. Solar reflectance and thermal emittance are the material properties that differentiate a cool roof from a conventional roof. Solar reflectance and thermal emittance determine the steady state temperature a roof will reach during a warm day. A roof’s steady state temperature when referenced to black and white surface temperatures, derives the Solar Reflectance Index (SRI). Roofs with a larger solar reflectance index values are more energy efficient. Other topics in this article include the environmental benefits cool roofs provide, cool roofs in cool climates, as well as roof types and cool roof alternatives.

Conventional roof heat gain

All roofs absorb solar radiation emitted by the sun. While roofs absorb sunlight, the absorbed energy results in higher roof temperatures. Solar energy absorbed by a roof transfers through the roofing materials to inside the attic space via conductive heat transfer. As a result, this process causes the attic space to warm up. The heat then radiates down into the living space below as heat naturally transfers from warmer to cooler spaces.

Heat transfer into a building is referred to as heat gain and a roofs contribution to this can be substantial. Air conditioning systems operate to alleviate heat gain and maintain a comfortable living space by lowering the temperature to the thermostat setting. Buildings with conventional roofs generally have higher heat gains. This results in either the air conditioning operating more often, or the living space to become uncomfortable. Buildings with cool roofs have less heat gain, resulting in either less air conditioning operation or the living space becoming more comfortable.

How a cool roof works

Cool roofs reflect and emit more sunlight and absorb less solar energy compared to conventional roofs. This results in a portion of the suns solar radiation returning to the atmosphere and less transferring into the building below.

Advancements in cool roof technology now allow for a roof to reflect a wide range of light wavelengths. These wavelengths include infrared, visible, as well as ultraviolet, all of which are emitted by the sun. Also, many cool roofs have high thermal emittance, which allows for more absorbed heat to quickly radiate towards the atmosphere.

The ability of a cool roof to reflect and emit solar radiation, reduces the surface temperature of the roof. The decrease in roof temperature, subsequently, reduces the realized heat gain inside the building. The reduced heat gain lowers air conditioning load requirements, therefore saving energy and money.

Note

Cool roofs provide energy saving when installed on roofs with proper attic insulation. They are not a direct replacement for insulation as the roof or attic will never be cooler than ambient temperature. Installing a cool roof with no insulation, is similar to air conditioning a building while leaving some windows and doors open. Insulation reduces heat gains or losses through a building at a rate proportional to the temperature difference between the living and outdoor spaces. Refer to How to install blown-in attic insulation for more information.

Cool Roof Coating

Henry 887 Tropi-Cool, 5 Gallon, 100% silicone white roof coating, premium moisture cure coating designed to reflect the sun’s heat & UV rays as well as protect many types of roofs.

Material properties of cool roofs

Solar reflectance and thermal emittance are the material properties that determine if the roofing materials meet the cool roof criteria. These measurements determine the steady state roof surface temperature according to the ASTM E 1980 standard. The steady state surface temperature determines the solar reflectance index (SRI) of the roofing material. Industry as well as consumers, use the solar reflectance index to compare roofing materials. The larger the solar reflectance index, the cooler the roof will remain in the sun.

Solar Reflectance

Solar reflectance is a measurement on a scale of 0 to 1 of the amount of sunlight that a roofing material reflects. The sunlight that does not reflect, is absorbed as heat into the roof. For example, if a roofing materials, solar reflectance measurement is 0.41, 41% of the sunlight reflects from the roof and 59% of the sunlight is absorbed as heat into the roof. Solar reflectance of roofing materials varies drastically from 0.05 to 0.2 on conventional darker roofs compared to 0.9 or greater on some cool roofs.

Thermal Emittance

Thermal emittance is a measurement on a scale of 0 to 1 of how effectively a roofing material is able to radiate heat. The heat that the roof does absorb, needs to easily escape; otherwise conductive heat transfer will contribute to building heat gain. Roofing materials with high thermal emittance, radiate heat quickly through the path of least resistance. As a result, most of the heat will radiate to the atmosphere and use convective heat transfer in the process. A portion of the heat will conduct through the roofing material and contribute to building heat gain.

Bare aluminum roofs have a low thermal emittance, as a result, they do not effectively radiate heat to the atmosphere. They retain the absorbed heat and have a higher steady state surface temperature as a result. Aluminum roofs with high solar reflectance and low thermal emittance stay warmer in the sun compared to cool roofs with high solar reflectance and thermal emittance.

Solar Reflectance Index (SRI)

The solar reflectance index (SRI) measures the ability of a roofing material’s surface to stay cool in the sun. SRI measures a roofs steady state surface temperature in relation to reference black and white surface temperatures at standard solar and ambient conditions.

SRI=\frac { { T }_{ SB }-{ T }_{ SE } }{ { T }_{ SB }-{ T }_{ SW } } \times 100\small \begin{alignedat}{3}{ T }_{ SB }&=Reference\; Black \; Surface\; Temp\\{ T }_{ SW }&=Reference\; White\; Surface\; Temp\\{ T }_{ SE }&=Steady\; State\; Surface\; Temp\end{alignedat}

TSB has a steady state surface temperature of 355.6 oK, based on a solar reflectance of 0.05 and thermal emittance of 0.90. Additionally, TSB has an SRI = 0.

TSW has a steady state surface temperature of 317.8 oK, based on a solar reflectance of 0.8 and thermal emittance of 0.90. Additionally, TSW has an SRI = 100.

Note

It is possible for cool roof materials to have a solar reflectance index greater than 100. For example, if a roofing material had a solar reflectance and thermal emittance equal to 0.9, its steady state surface temperature would be 312.3oK. This would result in an SRI equal to 114, and a roof that is cooler than a steady state white surface temperature.

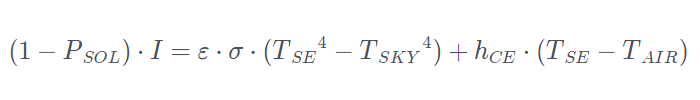

How to Calculate Steady State Surface Temperature

The steady state roof surface temperature is calculated according to the ASTM E 1980 standard. This standard uses two material properties (solar reflectance and thermal emittance) and four environmental properties (insolation, convective coefficient, air temperature as well as sky temperature) to determine steady state roof surface temperature.

(1-{ P }_{ SOL })\cdot I=\varepsilon \cdot \sigma \cdot ({ { T }_{ SE } }^{ 4 }-{ { T }_{ SKY } }^{ 4 })+{ h }_{ CE }\cdot ({ { T }_{ SE } }-{ T }_{ AIR })

PSOL = solar reflectance

I = insolation (1000 W / m2)

Ɛ = thermal emittance

σ = constant of proportionality (5.67E-8 W/ m2 oK4)

TSE = steady state surface temperature (oK)

TSKY = sky temperature 300 (oK)

hCE = convective heat transfer coefficient (12 W / m2 oK) – medium wind

TAIR = air temperature 310 (oK)

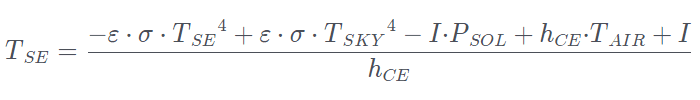

Rearrange the ASTM E 1980 equation to iteratively solve for the steady state surface temperature. Solar reflectance and thermal emittance are provided by the roofing manufacturer. The ASTM standard provides static values for insolation, constant of proportionality, sky temperature as well as air temperature.

{ T }_{ SE }=\frac { -\varepsilon \cdot \sigma \cdot { { T }_{ SE } }^{ 4 }+\varepsilon \cdot \sigma \cdot { { T }_{ SKY } }^{ 4 }-{ I\cdot }{ { P }_{ SOL }+{ h }_{ CE }{ \cdot T }_{ AIR }+{ I } } }{ { h }_{ CE } }

To solve for TSE iteratively, you first need to guess a steady state surface temperature and then insert that number into the TSE4 portion of the equation. Then solve for TSE. The answer for TSE then reinserts into the TSE4 portion of the equation again. Repeat this process until the answer for TSE does not change or changes are minor (to the hundredth or thousandth decimal place).

ASTM steady state surface temperature

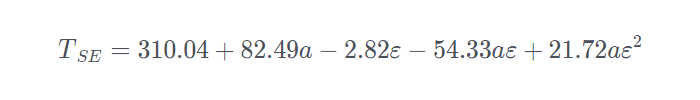

Alternatively, the ASTM standard provides an equation to estimate the steady state surface temperature with an accuracy of 1oK.

{ T }_{ SE }=310.04+82.49a-2.82\varepsilon -54.33a\varepsilon +21.72a{ \varepsilon }^{ 2 }

Ɛ = thermal emittance

PSOL = solar reflectance

a = solar absorptance (1 – PSOL)

The steady state temperature unit used in the ASTM standard is in degrees Kelvin. To convert this to degrees Celsius, simply subtract 273. From the example where both solar reflectance and thermal emittance were equal to 0.9, the steady state surface temperature would therefore be 39.3oC. If you reside in the U.S.A., convert degrees Celsius to degrees Fahrenheit by multiplying 9/5 and adding 32 to get 102.7oF.

Note

The Cool Roof Rating Council (CRRC) is a non-profit organization that provides a non-biased third-party evaluation of reflectance, emittance and SRI. Refer to their CRRC website to compare roofing material SRI ratings.

Energy saving benefits of cool roofs

Conventional darker roof surfaces can have surface temperatures that exceed ambient temperatures by 82oF or more. Comparatively, cool roof surfaces can have surface temperatures that exceed ambient temperatures by only 14oF or less. Cool roofs provide roof surface temperatures between 60-70oF cooler than conventional roofs. This reduces heat transfer contribution into the building directly from the roof. The reduced heat transfer decreases air conditioning needs which therefore reduces energy consumption.

According to the U.S. Department of Energy, researchers have measured energy savings upwards of 10-15% of homes with cool roofs. The energy savings cool roofs provide vary depending on climate, building design, as well as HVAC equipment design/efficiency.

Climate has a large impact on expected energy savings. Energy savings occur throughout the year in climates with year round high average temperatures. Whereas mixed climates may only benefit during the spring and summer months. Building design, such as roof pitch and the amount of attic insulation also influence the expected energy savings provided from cool roofs. Furthermore, buildings with steep roofs will benefit more from a cool roof as they have more surface area providing heat gain. Additionally, buildings with poor attic insulation will benefit more from cool roofs as there is less temperature difference between the attic and living space. HVAC equipment efficiency ratings and design also affect energy savings. Cool roofs provide greater energy savings when HVAC equipment/ductwork are installed within the attic space or when the equipment is old or less efficient to operate.

Oak Ridge National Laboratory has a cool roof calculator that calculates expected energy savings based off of the information you enter in. If you enter in the price you pay for electricity and natural gas, the calculator will also calculate the amount of money you will save.

Cool roofs in cool climates

Cool roofs provide the greatest amount of energy savings in hot climates, however, there are still advantages to using cool roofs in cold climates. Cold climates still have air conditioning requirements during the warm summer months. Cool roofs can reduce or eliminate these air conditioning requirements.

The Oak Ridge National Laboratory’s cool roof calculator calculates both the energy savings and energy losses, commonly referred to as the heating penalty. The heating penalty takes into account that anything above absolute zero (0oK / -273oC / -459oF) emits thermal radiation. Therefore, in mixed and cold climates during a cold winter day, a non-snow covered roof still has the potential to absorb solar radiation. Under these circumstances, cool roofs reduce the amount of thermal radiation the roof absorbs, therefore they can increase the amount of energy required to heat the building.

Winter heating penalties in cool climates are eliminated when cool roofs have snow cover. There is no heating penalty because snow is Earths most reflective natural surface. Snow has a solar reflectance between 0.7 and 0.9. Cool roofs in cool climates provide summer energy savings with no heating penalty if roofs have winter snow coverage.

If you live in a climate with cold winters, however, snow does not accumulate on roofs, it would be best to use the Oak Ridge National Laboratory’s cool roof calculator. The calculator will help you evaluate if the summer energy savings outweigh the heating penalty.

Environmental benefits of cool roofs

Replacing, modifying or building a roof using cool roof materials, decreases air conditioning requirements, resulting in less energy consumption. As a result, there will be fewer emissions of greenhouse gases. Greenhouse gas emissions, reduce because power plants consume less fossil fuels to provide the reduced energy demand.

There is also an environmental benefit when multiple buildings in an urban area use cool roofs in a collaborative effort. The dense concentration of buildings and other non-reflective surfaces in urban areas absorb solar radiation throughout the day. This retained heat gradually releases and contributes to warming the urban core. Temperatures of urban areas measure 2 to 5oF warmer than their surrounding rural areas. The higher temperature within urban areas is known as the urban heat island effect. The urban heat island effect has negative impacts towards the environment because it results in increased air conditioning requirements.

Accordingly, the urban heat island effect has prompted changes to building codes in many cities throughout the United States. Even cities that show a considerable amount of heating penalties using the U.S. Department of Energy’s cool roof calculator, have mandated cool roofs.

Roof types and cool roof alternatives

Roofs can be divided into two main categories: low slope and steep slope. Low slope roofs have a slope equal to or less than 14o (3-12). Steep slope roofs have a slope greater than 14o (3-12). Low slope roofing materials typically consist of built-up roofing (BUR), modified bitumen (MB), spray polyurethane foam (SPF), single-ply thermoplastic olefin (TPO), single-ply ethylene, propylene, diene monomer (EPDM) as well as single-ply polyvinyl chloride (PVC). Steep slope roofing materials typically consist of asphalt/composite shingles, clay/concrete tile, and metal. When building a new roof, all of these roof types can meet the cool roof criteria. When modifying an old roof, most of these roof types can be adapted to meet cool roof requirements.

Built-Up Roof (BUR)

Built up roofing is the most common traditionally used roofing system for low sloped roofs within the United States. Built up roofing consists of multiple layers of asphalt and reinforced roofing fabric to form a two to five layer roofing membrane. Depending on the age of the roof, coal tar may have been used instead of asphalt. The surface of built up roofing is typically gravel that embeds into the hot asphalt. Newly constructed built up roofing can be fitted with a UV-resistant fiberglass cap-sheet that meets cool roof standards. Alternatively, applying cool roof coatings to existing built up roofing will increase the roofs solar reflectance and thermal emittance to meet cool roof standards.

Modified Bitumen (MB)

Modified bitumen is an asphalt membrane that has been modified with plastic to give the membrane plasticized and rubberized qualities. The polymers used to modify the asphalt are either atactic polypropylene (APP) or styrene butadiene styrene (SBS). The modified bitumen membrane sheets are typically heat welded together and installed over asphalt or built up roofing. Newly constructed modified bitumen roofing can be fitted with a UV-resistant fiberglass cap-sheet that meets cool roof standards. Alternatively, applying cool roof coatings to existing modified bitumen roofing will increase the roofs solar reflectance and thermal emittance to meet cool roof standards.

Spray Polyurethane Foam (SPF)

Spray polyurethane foam roofs are sprayed onto a roof in a liquid form that hardens as it sets. The foam is composed of a heated one to one ratio of isocyanate and polyol. Additionally, the foam usually provides the roof with increased insulating properties. The coating of the spray polyurethane foam roof is how this type of roofing system meets cool roof standards.

Single-Ply Thermoplastic Olefin (TPO) / Single-Ply Ethylene, Propylene, Diene Monomer (EPDM) / Single-Ply Polyvinyl Chloride (PVC):

Single-ply membranes lay down over a roof in a single layer. Thermoset and thermoplastic are the two main types of single-ply materials. A material is categorized as thermoset if it solidifies permanently by molecular cross linking after heating. A material is considered thermoplastic if it can repeatedly soften when heated and harden when cooled. TPO and PVC are thermoplastic materials whereas EPDM is a thermoset material. Newly constructed single-ply roofing can be specified with a surface that has a high solar reflectance to meet cool roof standards. Alternatively, applying cool roof coatings to existing single-ply roofing will increase the roofs solar reflectance and thermal emittance to meet cool roof standards.

Asphalt/Composite shingles

Shingled roofs consist of overlapping asphalt/composite panels used on steep slope roofs for waterproofing. Shingled roofs are one of the most widely installed roofing systems in residential buildings. The wide use of shingled roofing is because of relatively low upfront costs and ease of installation. Cool roof asphalt shingles incorporate granules with high solar reflectance. Only newly built roofs or replacing exiting shingled roofs with a cool roof shingles is permissible to achieve the cool roof standards.

Applying a cool coating to existing shingles will generally void most shingle manufacturer’s warranty. Also, most local building codes do not permit coating existing shingles. The reason for this is based on the design as well as how shingles are used to waterproof a roof. Shingles, use gravity to drain water over the top of the shingle and down the roof. Water can sometimes travel underneath the shingle and down the underlayment installed beneath the shingle. This can occur from large winds or more commonly from large volumes of water, especially on roof valleys where two external building walls meet.

Shingled roofs are vapor permeable, which allows them to dry from underneath once the rain has stopped. Most cool roof coatings are impermeable, which as a result, may lead to drying issues if they are applied on top of shingles. Also, the required drainage paths may become blocked or restricted leading to water damage.

Shingle manufactures have manufactured cool roof shingles that meet both Energy Star and Leadership in Energy and Environmental Design (LEED) requirements. CetainTeed Landmark Solaris, Owens Corning Duration Premium Cool as well as GAF Timberline Cool Series are a few worth looking at.

Tile roofing

Tile roofs can be made of clay, slate, as well as concrete. Clay and slate tiles come from the ground, so their colors differ depending on the earth’s composition. Some varieties will naturally be reflective enough to achieve cool roof standards. Tiles can be also be glazed to provide waterproofing or coating to provide customized colors and surface properties. These surface treatments can transform tiles with low solar reflectance into cool roof tiles.

Metal roofing

Metal roofing is known for its longevity and impermeability. The initial cost to install a metal roof is high, however, based on its longevity, it may become less expensive than asphalt shingles in the long term. Newly constructed metal roofing can be specified with paint that has a high solar reflectance to meet cool roof standards. Alternatively, applying cool roof coatings to existing metal roofing will increase the roofs solar reflectance and thermal emittance to meet cool roof standards.

How to prepare and coat a roof with a cool roof coating

Step 1

Clean roof by removing debris followed by pressure washing

Use a pressure washer and non-filming detergent TSP to wash the roof area. Ensure you use an adequate amount of pressure to clean the roof while avoiding excessive pressure that could inject water into the roofing substrate. Use a stiff bristle brush and additional TSP to remove any remaining contaminants. Rinse all detergent off the roof once the cleaning is complete and allow the roof to fully dry.

Electric Pressure Washer

The 1800 MAX PSI pressure washer has enough versatile cleaning power to overcome hundreds of grueling projects. This unit is certified by the Pressure Washer Manufacturers Association (PWMA).

Step 2

Test adhesion of cool roof coating

Apply an 11 mil coat of the cool roof coating to three test areas on the roof. Use a wet film thickness gauge to accurately measure the thickness of the coating. While the cool roof coating is still wet, embed a 1 inch by 6 inch fabric test strip into the coating. Leave 2 inches of the fabric test strip out of the coating to provide a handle to pull on afterwards. Apply another 11 mil coat over the fabric and test areas, again leaving the 2 inch handle uncoated. Leave the three test areas to cure for 72 hours before checking the adhesion quality.

After 72 hours, pull upwards on the fabric test strip handles. If lifting the fabric is difficult or if the coating underneath the fabric remains on the roof, the adhesion is good. The adhesion is poor if the fabric lifts easily or if all of the coating pulls up from the roof. If the adhesion is poor, apply a primer to the roof before applying the cool roof coating.

Wet Film Thickness Gauge

Wet film thickness gauges are designed to quickly and easily measure the thickness of coatings immediately after they have been applied to a substrate. The teeth or notches are graduated in MILS (0.001″).

Step 3

Apply cool roof coating

Installing cool roof coatings improperly may cause the coatings to flake off or wear out. Read the cool roof coating installation instructions before proceeding to apply the coating to your roof. Most cool roof coatings need to be thoroughly mixed using a paint mixer and are not supposed to be thinned. Apply the coating with a minimum coating thickness of 22 mil using a ½ inch to 1 inch NAP lint free roller. Check the coating thickness using the wet film thickness gauge while applying the coating to ensure uniform thickness throughout.

Cool roof SRI requirements

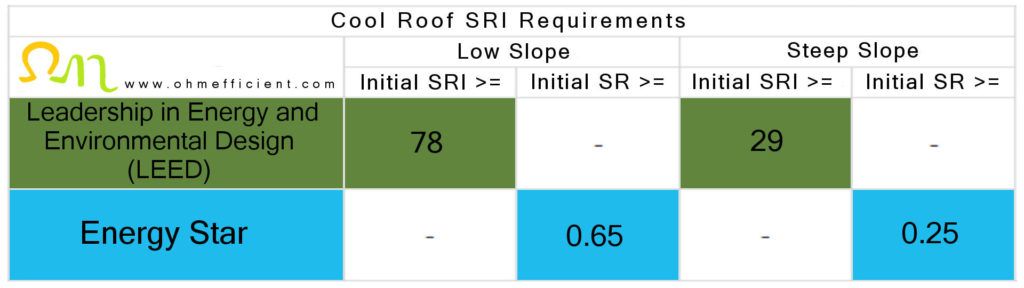

Cool roof requirements depend on the roof’s slope. The requirements are more lenient for steep slope roofs. There is potential for too much reflection towards surrounding buildings if steep slope roofs have high SRI, hence the less stringent requirements.

Parts and tools required

Cool Roof Coating

Primer (only if adhesion test results are poor)

Broom

Pressure Washer

TSP Non-Filming Detergent

Stiff Bristle Brush

Fabric Test Strips

Wet Film Thickness Gauge

Drill

Paint Mixer

References

Citation

Sandin, Olof & Nordin, Jan & Jonsson, Magnus. (2017). Reflective properties of hollow microspheres in cool roof coatings. Journal of Coatings Technology Research. 1-5. 10.1007/s11998-017-9973-y

Akbari, H., Levinson R., and Berdahl P. 1996. “ASTM Standards for Measuring slar Reflectance and Infrared Emittance of Construction Materials and Comparing their Steady-State Surface Temperatures”. Energy and Environment Division, Ernest Orlando Lawrence Berkeley National Laboratory. Presented at the American Council for Energy Efficient Economy Summer Study, August 1996.

Oak Ridge National Laboratory. (n.d.). Retrieved from

https://web.ornl.gov/sci/buildings/tools/cool-roof/

Cool Roof Rating Council. (n.d.). Retrieved from

https://coolroofs.org/directory

Related articles

Radiant barriers lower air conditioning costs

Perforated radiant barriers enhance attic insulation in cold climates

How to install blown-in attic insulation